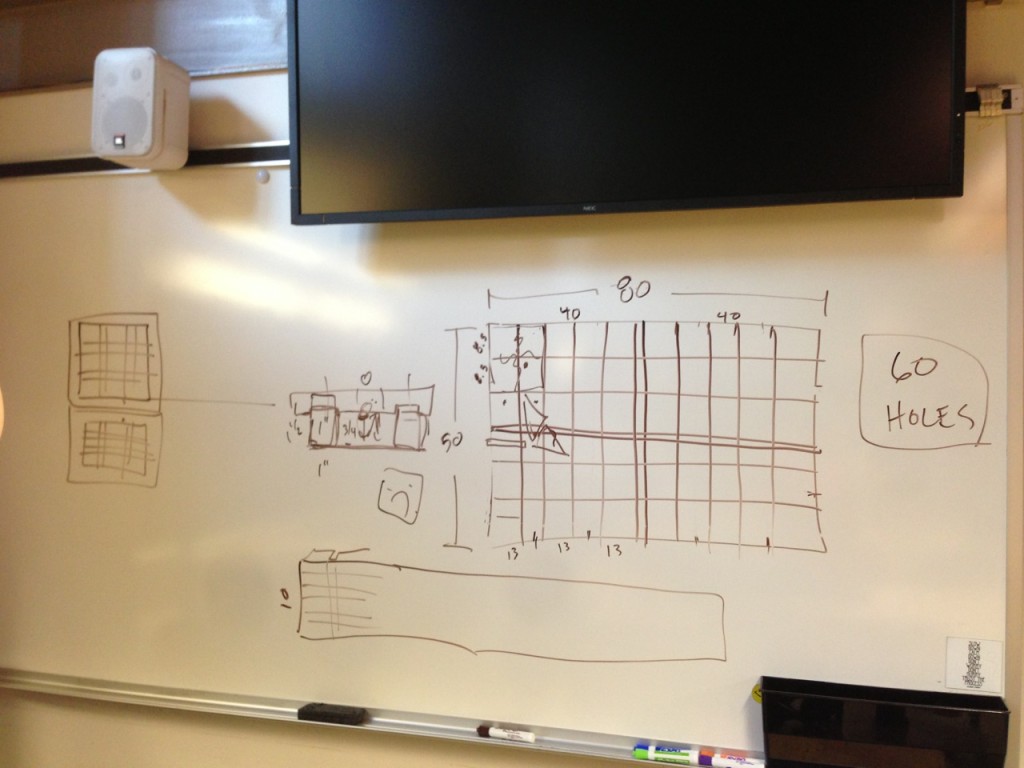

With the projection surface finalized, the next step was planning the frame itself. The amazing Brian Slocum from Lehigh University’s Design Labs was incredibly helpful in this process. We decided a basic scale for the frame (which later changed a bit), and Brian suggested that the servo attachments should be modular so they could be repositioned to align with the projections surface.

This was later scaled down to 8 columns rather than 10. The split in the middle would allow for the piece to be disassembled and transported.

The next step was to create a miniature version of the piece for further prototyping

The “servo” would be attached to the modular wood piece, which would be secured to the frame itself.

Thread prototype on mini-frame.

Which pushes the spandex, which pushes the pushes the foam board. Once that functioned correctly, I moved to an actual servo. I used the HS-311 from Hitec because it was inexpensive and had a reasonable amount of power. Powered and controlled with an arduino:

Servo test with rigid connection:

Servo Test with joint connection:

The view from in front of the foam projection surface: